June 27, 2024

Mastering Refrigeration Monitoring Systems: A Comprehensive Guide to Understanding and Preventing Reading Fluctuations for Refrigeration Monitoring Systems

Refrigeration monitoring systems are indispensable tools for businesses that rely on precise temperature control. They offer valuable insights into energy consumption, temperature stability, and pressure levels, ensuring the quality and safety of stored products. However, fluctuations in readings can be a source of confusion and concern. In this comprehensive guide, we’ll delve into the intricacies

Read More

September 2, 2022

CDC Digital Data Logger Requirements

According to the CDC, recent statistics reveal how many children have eight important vaccination doses by the age of 24 months. The highest percentages are among doses for MMR (Measles, Mumps, Rubella), Hepatitis B, and Chickenpox or Varicella, with over 90% of children 24 months and under who have it. A digital data logger is

Read More

August 3, 2022

Temperature and Humidity Monitor for Cleanroom: Is It Accurate?

Did you know that the size of the cleanroom technology global market was valued at $4 billion in 2020? Additionally, this market is expected to undergo an expansion at a CAGR (compound annual growth rate) of 5.4% between 2021 and 2028. If you’re in the cleanroom industry and you have a cleanroom, you might feel stressed.

Read More

November 9, 2021

Temperature and Humidity Monitoring in the Pharmaceutical Industry

There are over 26,000 drug store businesses and pharmacies in the US. The growth of these businesses has been 3% in 2021, and the states where the most pharmacies are present are California, New York, and Texas. Something that pharmacy business owners have to consider when storing their medications is temperature and humidity monitoring. The same goes

Read More

August 17, 2021

A Guide to Laboratory Temperature Monitoring

Achieving and maintaining proper temperature in a laboratory is not as simple as it seems. Remote temperature monitoring systems made headlines last year during the COVID-19 vaccine rollouts. The Pfizer vaccine requires a cold storage temperature of -70C. You must store the Moderna vaccine at -20C. There were many logistical concerns to work out when

Read More

June 15, 2021

Pharmaceutical Temperature Mapping: How the System Works

Cold chain storage is an important segment of the pharmaceutical industry. It’s expected to grow to be worth $21 billion by 2024. Medications are sensitive to even the slightest temperature changes. Many become useless when exposed to heat. This causes major losses for consumers and pharmaceutical manufacturers. Medications need to be monitored from the moment they arrive

Read More

February 25, 2021

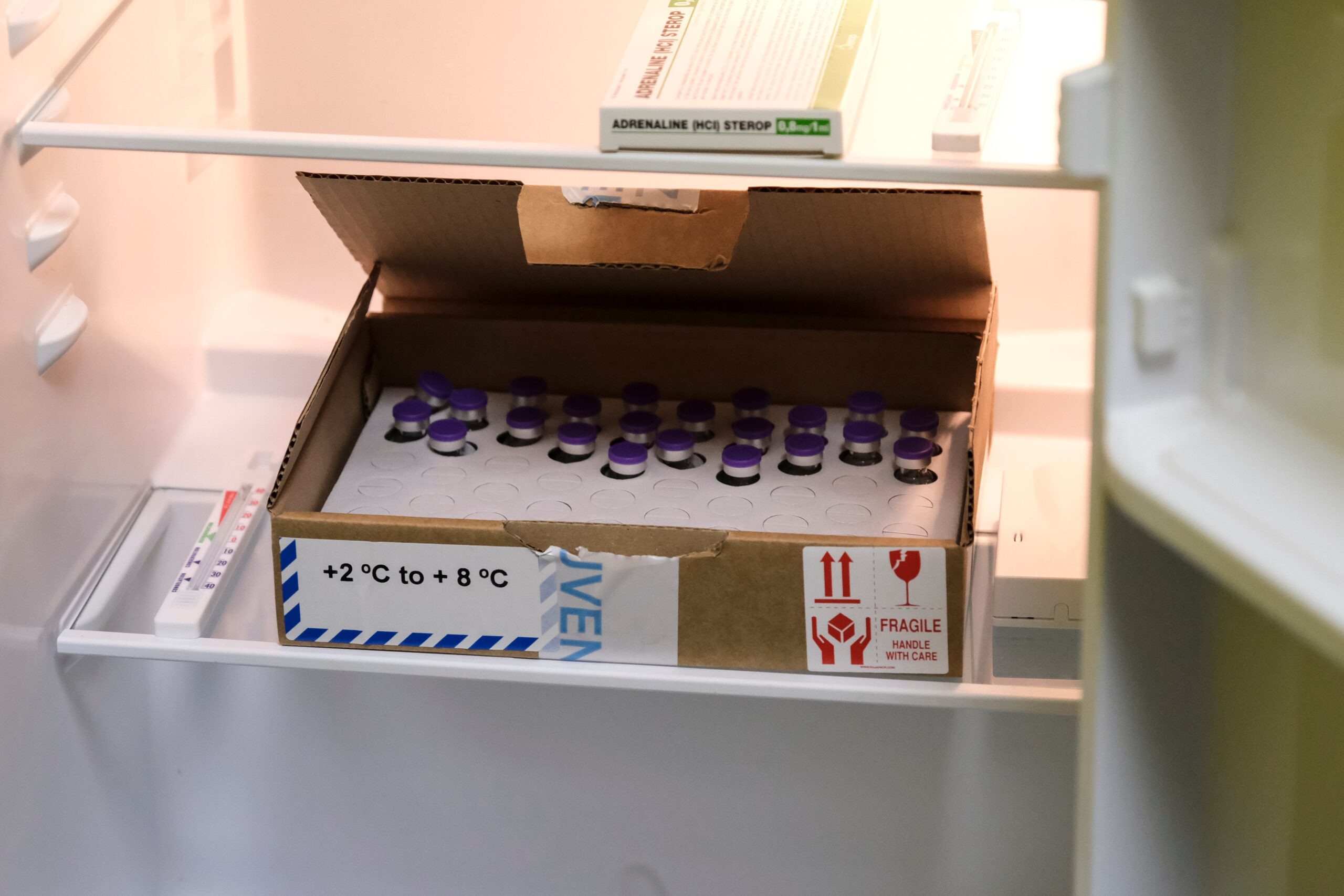

The Importance of Vaccine Temperature Monitoring in 2021

Vaccine temperature monitoring is crucial when it comes to storing any vaccine. Storing the vaccine properly protects its ultimate potency. Think about it this way, nobody wants a vaccine that doesn’t have full capability. COVID-19 is rampant in America. It is important now more than ever to make sure that all vaccines are in their

Read More

January 25, 2021

Your Ultimate Guide to Pharmaceutical Temperature Mapping

Drug manufacturers suffer billions of dollars in losses each year by failing to keep medicines and vaccines at correct temperatures. This does not even include costs for resupplying the drugs. Temperatures can exceed recommended ranges anywhere along the supply chain. Proper pharmaceutical temperature mapping prevents these temperature fluctuations. As a result, manufacturers save billions of dollars in ruined

Read More

January 12, 2021

Pharmaceutical Temperature Mapping: Uses and Methodology

Everyone who manufactures, stores, or transports pharmaceuticals must regulate temperatures. One survey looked at how often these companies experience variations. About 44.6 percent of survey participants reported many temperature changes each year.Monthly temperature changes occurred according to 16 percent of respondents. Two of every five or 41 percent of changes were more than four degrees. Another 21

Read More

October 28, 2020

Pharmaceutical Temperature Mapping: Why Is It Needed?

The Biopharma industry loses about $35 billion annually due to temperature control failures. Does your business produce or handle pharmaceutical products? How confident do you feel in your refrigeration or freezer equipment? It’s important for all biopharma companies to do regular temperature mapping. This decreases lost revenue and the risk of selling harmful or ineffective drugs. Continue

Read More