April 25, 2024

Understanding the Benefits and Applications of Differential Pressure Sensors

As a leader in the environmental monitoring industry, SensoScientific understands the vital role differential pressure (DP) sensors play in diverse applications. These sensors provide essential data for monitoring and controlling pressure differentials between two points in a system. This precision is crucial for everything from ensuring the safe operation of complex machinery to maintaining critical environments in healthcare facilities. Our commitment to innovation in Internet-of-Things (IoT) technology and the development of scalable wireless environmental monitoring systems has positioned us to offer unparalleled value and insights into the world of DP sensors.

What are Differential Pressure Sensors?

At SensoScientific, we specialize in precision differential pressure (DP) sensors. These sensors are uniquely designed to measure the pressure differential between two points, unlike absolute pressure sensors which reference a vacuum. This distinction is critical for applications where maintaining a consistent pressure difference is paramount, ensuring system stability and adherence to compliance standards.

How Do Differential Pressure Sensors Work?

Understanding how differential pressure (DP) sensors work is key to their effective use in monitoring critical systems. Here are two common types frequently integrated into our solutions:

- Diaphragm-based DP sensors: These sensors utilize a thin, flexible diaphragm that separates the two pressure inputs. When a pressure difference is applied across the diaphragm, it deflects proportionally to the pressure differential. This deflection is then converted into an electrical signal using various methods, such as strain gauges, piezoresistive elements, or capacitive sensing. These versatile sensors offer the precision needed for real-time data collection, crucial for documenting compliance and ensuring system stability.

- Duct-mounted DP sensors: These sensors are designed for airflow measurement applications. They typically consist of multiple tubes or passages that expose the sensor to the high and low pressure sides of the airflow. The pressure differential creates a pressure difference across a sensing element within the sensor, which is then converted into an electrical signal. This technology provides reliable airflow measurement, offering insights vital to optimizing building environments and meeting regulatory reporting requirements.

Applications of Differential Pressure Sensors

Our differential pressure (DP) sensor solutions are designed for a wide range of applications, with particular strengths in industries we specialize in, such as healthcare, laboratories, pharmaceutical manufacturing, and food processing. Here are some prominent examples of how our technology supports these sectors and others:

- HVAC (Heating, Ventilation, and Air Conditioning) Systems: SensoScientific’s DP sensors streamline HVAC monitoring by providing real-time data on airflow, filter performance, and pressure drops. This precision is essential for maintaining system efficiency, ensuring proper ventilation, and simplifying energy efficiency and air quality compliance reporting.

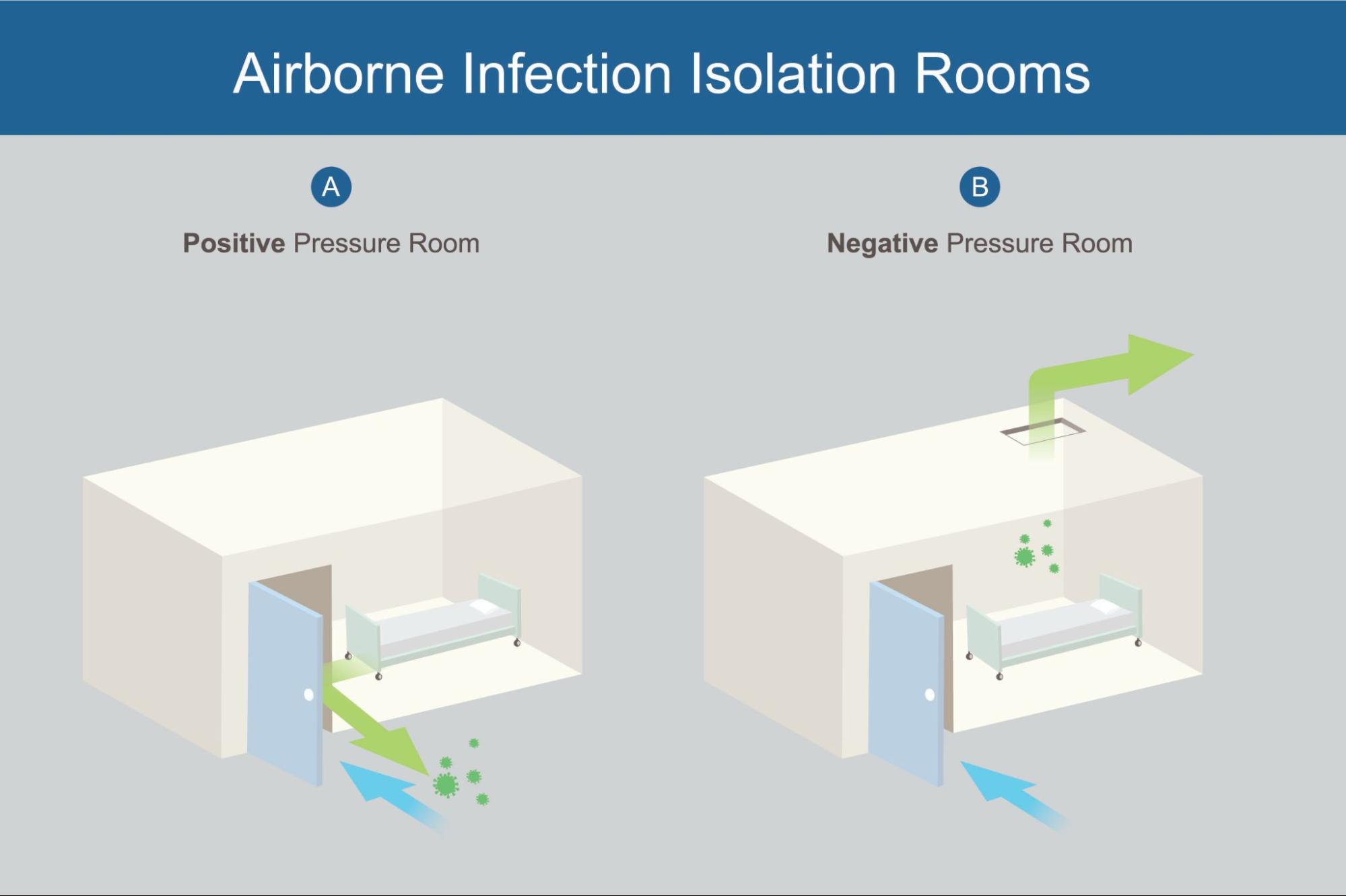

- Building Automation: Our DP sensors are integrated into building automation systems to control pressure differentials in stairwells, elevator shafts, and cleanrooms. In healthcare and laboratory environments, this technology is essential for ensuring proper air circulation and preventing the spread of airborne contaminants.

- Medical Facilities: In healthcare settings, accuracy and reliability are paramount. Our DP sensors are critical for maintaining negative pressure isolation rooms, continuously monitoring the pressure differential to ensure the integrity of the isolation environment.

- Industrial Processes: DP sensors are extensively used in industrial processes to monitor pressure differentials across filters, pumps, and compressors. They also play a role in leak detection applications, where a sudden drop in pressure differential can indicate a leak in the system, allowing for proactive maintenance and minimizing downtime.

- Aerospace Industry: DP sensors are essential for various applications in the aerospace industry, including monitoring cabin pressure in aircraft, measuring fuel pressure in engines, and ensuring proper airflow in wind tunnels. Our sensors are designed to meet the rigorous demands of this industry.

Benefits of Using Differential Pressure Sensors

With our in-depth knowledge of differential pressure (DP) sensor technology, we’ve engineered solutions that deliver benefits beyond the basics:

- Versatility: Our DP sensors are adaptable to measure a wide range of pressure differentials across various gases, liquids, and challenging applications.

- Accuracy & Reliability: Our commitment to precision ensures accurate, dependable data vital for system optimization and regulatory adherence.

- Durability: DP sensors are built to withstand harsh environments and can operate reliably for extended periods, maximizing your investment.

- Ease of Integration: Our sensors are designed for seamless implementation, simplifying system upgrades and expansions.

- Customer Support: Our technical expertise and ongoing support ensure you get the most out of your DP sensor solution.

Considerations When Choosing a Differential Pressure Sensor

Selecting the ideal differential pressure (DP) sensor requires careful analysis. At SensoScientific, we consider these factors to provide tailored solutions:

- Pressure Range: Our diverse sensor portfolio offers options to match your expected pressure differential.

- Accuracy Requirements: We offer sensors with varying accuracy levels, ensuring you get the precision you need without overpaying.

- Media Compatibility: Our sensors are designed with robust materials to handle a wide array of gases and liquids.

- Environmental Conditions: Whether your application involves harsh environments or controlled settings, we have DP sensors designed to thrive.

- Regulatory Compliance: We understand the importance of meeting regulatory standards and can recommend sensors that support accurate data collection and streamlined reporting.

- Technical Support: Our experts are always available to assist with sensor selection and system integration.

The Role of Differential Pressure Sensors in Negative Pressure Isolation Rooms

Negative pressure isolation rooms are essential for patient safety. Our differential pressure (DP) sensor solutions are designed specifically for these critical healthcare environments. Here’s how they help maintain a safe isolation environment:

- Continuous Monitoring: Our DP sensors meticulously monitor the pressure differential between the inside of the room and the corridor or anteroom.

- Real-Time Feedback: Sensors provide real-time feedback to a control system that regulates the room’s exhaust fan, ensuring the desired negative pressure is maintained.

- Proactive Alerts: If the pressure differential drops below a specified threshold, the control system increases the fan speed and may trigger an alarm, alerting staff of the potential breach in containment.

- Simplified Compliance: Our solutions offer automated data logging and reporting capabilities, streamlining compliance processes for healthcare facilities.\

Choose a Differential Pressure Monitoring System that Works Best for Your Facility’s Needs

Differential pressure sensors hold the key to optimizing systems, safeguarding environments, and driving innovation across diverse industries. At SensoScientific, we’re committed to leading the charge with cutting-edge differential pressure (DP) sensor solutions that help our clients achieve their unique goals. Our focus on precision, reliability, automated compliance, and ongoing support ensures you get the most value as differential pressure technology continues to evolve. Contact us today to learn how our solutions can transform your operations.